+86-769-85303229 +86-13763283864 jennyguo@fazcwj.com

Views: 0 Author: Site Editor Publish Time: 2025-08-11 Origin: Site

A spring loaded plunger is a small device with a spring inside. The spring pushes a pin or ball into place. It helps hold, lock, or position parts in equipment. People like it because it makes strong connections. It also lets you change things quickly. Many industries use these plungers, including:

Machine tools and woodwork equipment

Medical devices

Consumer products

Sports and recreational equipment

These devices make work easier. They keep moving parts where they should be.

Spring loaded plungers have a spring inside. The spring pushes a pin or ball. This holds or locks parts in place. Machines work better with them. It is also easier to change parts.

You need to pick the right plunger for your job. Match its size, spring force, and material to your needs. This helps it work well and last longer.

Ball plungers are soft and good for light work. Pin plungers hold things tighter. They are better for heavy jobs.

Keep spring loaded plungers clean and oiled. This stops them from sticking. It also helps them work well for a long time.

These plungers save time and lower mistakes. They lock things by themselves. This makes them great for many jobs and industries.

A spring loaded plunger is a mechanical device used for positioning and holding parts in place. It uses a spring inside to push a pin or ball outward. When someone applies force, the tip moves back into the body. When the force goes away, the spring pushes the tip back out. This action helps keep parts locked or aligned. Engineers use the term "spring loaded plunger" to describe a component that can retract under pressure and return to its original spot when released. It works well for indexing, securing, and aligning workpieces. Different types, such as ball plungers and pin plungers, have unique tip designs and stroke lengths. The spring load, or the amount of force the spring can handle, sets the limits for how much pressure it can apply.

Note: The market for these devices keeps growing. Many industries want better positioning and locking systems. New designs now use smart sensors and eco-friendly materials. Some plungers are smaller to fit tight spaces. Others use advanced materials for harsh environments.

A spring loaded plunger has three main parts:

Plunger Tip: This part sits at the end. It can be a ball or a pin. The tip touches the part that needs to be held or locked.

Internal Compression Spring: The spring sits inside the body. It pushes the tip outward and controls the force.

Threaded Body: This part holds the spring and tip. It often has threads so users can screw it into place.

These parts work together to create reliable positioning. When someone pushes on the tip, the spring compresses. The tip moves back into the body. When the force stops, the spring pushes the tip back out. This action locks or holds parts in place. The design allows for quick fixing and releasing. Some plungers have special features, such as hand retractable tips or custom shapes for special jobs.

Here is a simple table showing the main parts and their functions:

Part | Function |

|---|---|

Plunger Tip | Contacts and holds the target component |

Internal Spring | Provides the pushing force |

Threaded Body | Houses the spring and tip; allows installation |

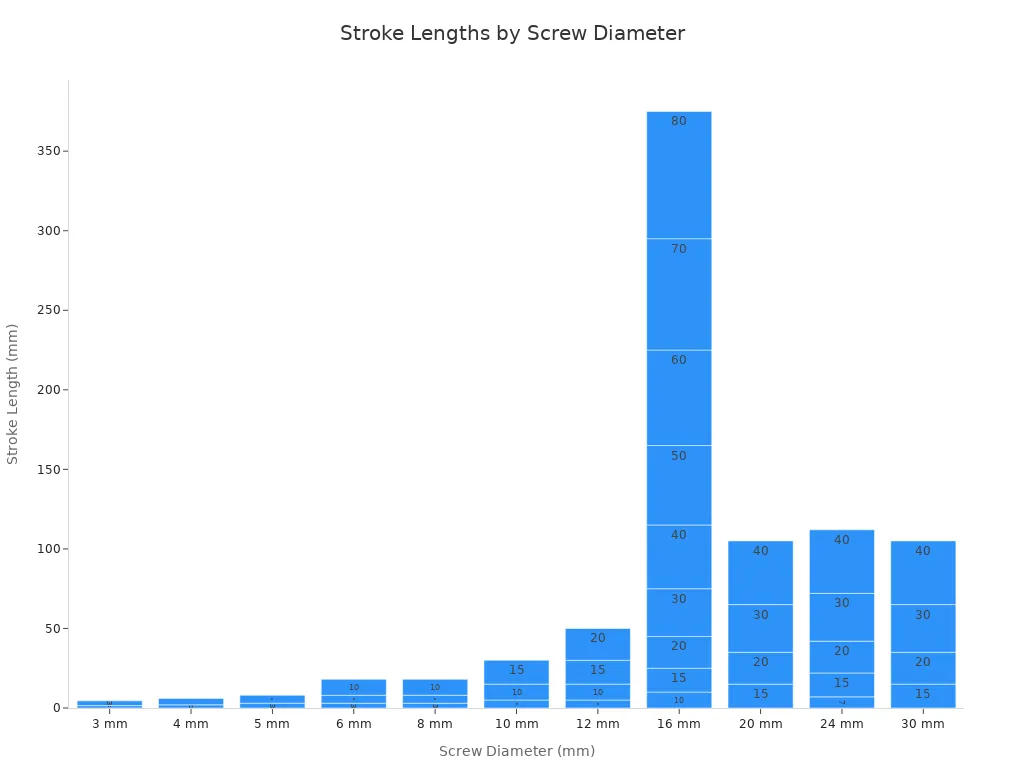

Many sizes and load ratings exist. The table below shows some standard dimensions for heavy load plungers:

Screw Diameter (mm) | Stroke Length (mm) | Load Type |

|---|---|---|

3 | 1.5 | Heavy Load |

4 | 2 | Heavy Load |

5 | 3 | Heavy Load |

6 | 5 | Heavy Load |

8 | 10 | Heavy Load |

10 | 15 | Heavy Load |

12 | 20 | Heavy Load |

16 | 40 | Heavy Load |

20 | 40 | Heavy Load |

24 | 30 | Heavy Load |

30 | 40 | Heavy Load |

Tip: When choosing a spring loaded plunger, check the size and load rating. These details help match the plunger to the job.

A spring loaded plunger works with a simple spring inside. The spring sits between the plunger tip and the body. It pushes the tip out with steady force. The spring can be in three main positions:

Free Height: The spring is fully stretched out. Nothing presses on it.

Working Height: The spring is partly squeezed. It gives the best holding force.

Maximum Compression: The spring is squeezed as much as it can be. The tip cannot go in any further.

The spring can get shorter or longer as needed. It gives a steady push to hold or let go of parts. This force stays the same each time, so parts line up right. The threaded body keeps the spring in place. It also keeps the spring squeezed just right. People can pick how strong the spring should be for their job. Some jobs need a soft touch. Others need a lot of strength.

Here is a table that shows force ranges for different plungers:

Parameter | Value/Range | Notes |

|---|---|---|

End Force Range | 0.125 to 200 lbs | Covers light to heavy end force designs |

Force Behavior | Increases with travel | Force rises as plunger compresses spring |

Some light spring loaded plungers give only a little force, about 0.09 to 0.22 pounds. Heavy-duty types can push up to 200 pounds. The spring keeps working well, even if there is shaking or stress. This makes it a good choice for many jobs.

Tip: Always pick the right spring force for your job. Too much force can break parts. Too little force might not hold things tight.

Locking and positioning are the main jobs of a spring loaded plunger. When you push the tip, the spring gets squeezed. The tip moves back into the body. When you stop pushing, the spring pushes the tip out again. This locks or holds parts in place.

Different plungers use this idea in special ways. For example:

Hand retractable plungers: You twist or pull a handle to pull the tip back fast.

Indexing plungers: The nose pulls back to unlock a part, then springs forward to lock it again.

Press fit and threaded plungers: These are easy to put in and lock by themselves.

A spring loaded plunger is great for lining up parts and locking them again and again. It locks by itself when parts match up. This saves time and makes work easier. Other locks, like cam levers or clamps, need more work and do not lock by themselves.

Here is a table to compare:

Feature/Aspect | Spring Loaded Plungers | Other Locking Devices |

|---|---|---|

Locking Mechanism | Spring-loaded tip or ball | Manual lever or clamp |

Function | Precise indexing and automatic engagement | Simple fastening or releasing |

Ease of Use | Quick, reliable, often one-handed | May need tools or more effort |

Application Suitability | Ideal for repeatable, adjustable locking | Best for general fastening |

Spring loaded plungers help hold, lock, cushion, support, or push out parts in machines. They work well in machines that need to be changed often. The spring keeps pushing, so parts stay put even if the machine shakes or moves.

Note: Keep plungers clean and oiled to stop them from sticking. If they get dirty or lined up wrong, they may not work. Check them often to keep them working smoothly.

Ball plungers have a round ball at the end. The ball sits on a spring inside the body. When you push the ball, it moves back. The spring pushes the ball out again. This makes the ball move smoothly. Ball plungers are good for light jobs and soft surfaces. People use them in furniture, drawers, and cabinets. They also work in wooden parts. The ball tip slides easily and does not scratch things.

Ball plungers can be made from different materials. Stainless steel and carbon steel are strong and do not rust easily. Brass and nylon are better for light jobs or when you need to protect surfaces.

Material | Performance Impact | Typical Applications |

|---|---|---|

Stainless Steel | Strong and does not rust | Used in tough places |

Carbon Steel | Strong, needs coating to stop rust | Used for heavy work |

Brass | Does not scratch, not as strong | Used for nice or soft surfaces |

Nylon | Does not scratch, light, does not rust | Used for light jobs and plastics |

Ball plungers are best when you want smooth and gentle holding.

Pin plungers have a thin pin at the end. The pin moves in and out with a spring. This type gives a stronger and more exact hold. Pin plungers can handle heavier jobs than ball plungers. They are used in machines, pumps, and valves.

Pin plungers come in many styles. Some have coatings to stop rust. Others have special shapes to make them stronger. Here is a table that shows some types and where they are used:

Type of Pin Plunger | Typical Applications | Industries / Settings |

|---|---|---|

Flanged Indexing Plungers | Hold panels or parts in place | Used in electrical boxes |

Press Fit Plungers | Hold workpieces or rollers | Used in factories |

Locking Indexing Plungers | Lock things that move a lot | Used in workstations |

Cam-action Indexing Plungers | Lock heavy things, quick to release | Used in building and big machines |

Pin plungers are good for locking and lining up parts in hard jobs.

Some spring loaded plungers are made for special jobs. Hand retractable plungers let you use one hand. You twist to lock or unlock the tip. Press fit plungers push in without threads. They work well in wood or plastic. Pull pin plungers have a ring for fast release. Push pin plungers have holes for adding knobs or grips.

Specialty Type | Unique Features | Applications |

|---|---|---|

Hand Retractable | Use with one hand, twist to lock | Used in factories and sports gear |

Press Fit | No threads, strong spring | Used in wood, plastic, or aluminum |

Pull Pin | Quick to release, has a ring | Used in tools and gates |

Push Pin | Has holes for knobs or grips | Used for holding or lining up parts |

These special plungers help in many jobs. They let you change things fast, hold parts tight, and put them in easily.

Spring loaded plungers are used in many fields. They help hold, lock, and line up parts during work. People use them in machine tools and woodworking machines. They are also found in adjustable fixtures. You can see them in things like cabinets, drawers, and sports gear. Engineers use them for quick and repeatable moves on factory lines. In cars and planes, they keep panels and moving parts in place. Medical devices need parts to line up just right, so designers pick plungers for this job.

A table below shows where these devices work well:

Application Area | Example Use Cases |

|---|---|

Machine Tools | Indexing, fixture positioning |

Woodworking | Drawer slides, cabinet latches |

Automotive | Securing panels, locking levers |

Aerospace | Fastening access doors, panels |

Medical Devices | Component alignment, retention |

Consumer Products | Sports gear, adjustable furniture |

Tip: Their small size lets them fit in tight spots. This makes them great for small assemblies.

These devices have many good points over old springs or locks.

They give steady force for holding and lining up parts.

They save time and cut down on mistakes, so work is faster.

The threaded body makes them easy to put in and use.

They lock parts tight, so things do not move by accident.

The spring helps keep parts lined up, which is important for holding work.

Some let you move parts fast, so you do not drop or break things.

They work in any position and last through many uses.

Spring loaded plungers cost less than many other devices. Their simple shape means you need fewer parts, so you save time and money. You can pick from ball, pin, or hand retractable types for different jobs. Stainless steel ones do not rust, so they are good for wet or tough places. Carbon steel plungers are best for dry, indoor spots but do not last in wet or chemical areas.

Material Type | Best Use Environment | Limitation in Harsh Conditions |

|---|---|---|

Stainless Steel | Wet, chemical, or outdoor | Few; handles most harsh conditions |

Carbon Steel | Dry, indoor | Rusts in moisture or chemicals |

Brass | Marine, electrical | Limited by specific application |

Zinc Plated | Light outdoor, moderate use | Not for extreme environments |

Note: Picking the right material helps plungers last longer and keeps things safe.

Picking the right plunger means thinking about many things. The place where you use it is very important. Vibration and shock can make a plunger not work well. Some plungers have locks to keep them from coming loose. In tough places, you need a plunger that does not rust. Stainless steel and silicon nitride are good for fighting wear and chemicals. If you pick the wrong one, it might fall out or stop working.

The table below lists what you should think about:

Factor | Description |

|---|---|

Plunger Type | Standard, stubby, ball, push-fit; each fits different space and load needs. |

End Force | Light to heavy; affects holding strength and how easy it is to retract. |

Travel Distance | Longer travel increases force due to spring compression. |

Thread Size | Must fit the mounting hole. |

Space Constraints | Stubby plungers fit tight spaces; long-travel types hold sheets or side loads. |

Hand-Operating Elements | Knobs, handles, or rings for manual use. |

Lock Out Feature | Holds the plunger in a retracted position for safety. |

Material Selection | Steel, stainless steel, Delrin®, nylon; pick for strength, corrosion, and temperature needs. |

Environmental Factors | Vibration, shock, and harsh conditions may need locking threads or special materials. |

Tip: Always pick a plunger that matches the job and place.

Engineers and workers can use some easy tips to pick the best plunger:

Look at the shape and size of the part you want to hold. Flat-bottom plungers are for flat things. Flange plungers fit curved or special shapes.

Make sure the plunger fits tight. If it does not, it can leak or break.

Pick the right end force. Too much force can break things. Too little force will not hold them.

Try the plunger in real life before using it for good. This helps you find problems early.

Use rust-proof plungers in wet or chemical places.

Add things like bushings or lanyards to help put it in and keep it safe.

Check guides, CAD models, and datasheets for more help.

People sometimes forget about the place where they use the plunger. They may pick the wrong material or skip testing. Do not use spring plungers where you need a fixed lock. Always pick the right type for how often you need to change things.

Note: Many companies have catalogs, help lines, and online tools to help you choose and install plungers.

Spring loaded plungers are important in many industries. They help parts stay in the right place. They also lock and line up parts so things work well. Stainless steel is the best for lasting a long time. People use these plungers in cars, planes, and electronics. Picking the right type and material makes things work better and safer.

Quick Takeaway Checklist:

Choose the best material for where you use it

Make sure the force and size fit your needs

Keep them clean and oiled

Knowing about these devices helps you work better and safer. Try using what you learned in your next project!

Manufacturers use stainless steel, carbon steel, brass, or nylon. Each material is good for different places. Stainless steel does not rust. Carbon steel is strong. Brass is gentle on soft things. Nylon stops scratches.

You screw or press the plunger into a hole. Some need threads to fit. Others just push in and stay. Always check if it fits before using it.

No, you cannot change the force after you install it. The spring force is set at the factory. If you want a different force, pick another plunger.

People use them in machines, furniture, sports gear, and medical tools. The table below shows where they are used:

Area | Example Use |

|---|---|

Machines | Fixture alignment |

Furniture | Drawer slides |

Sports Gear | Adjustable parts |

Medical | Device retention |

Keep it clean and put oil on it. Dirt or rust can make it stick. Check it often so it works for a long time.