+86-769-85303229 +86-13763283864 jennyguo@fazcwj.com

Views: 0 Author: Site Editor Publish Time: 2025-09-16 Origin: Site

You use a plastic ball plunger to move parts gently. Material is important. POM and PA work for everyday jobs. PEEK is better for hot or tough places. Ball plungers keep electronics and molds safe. They protect soft surfaces. Zhengchen Hardware makes plungers that are light and quiet. They do not make sparks. They are safe in small spaces.

Plastic ball plungers help hold parts softly in electronics and molds. Pick the right type for your assembly needs.

Materials are important! POM and PA work well for daily jobs. PEEK is best for high heat and tough places. Choose based on where you work.

Find ESD-safe and non-marring plungers to keep electronics and soft surfaces safe. This helps things work safely and well.

A plastic ball plunger helps hold parts in place. It uses a spring ball plunger mechanism. The ball moves in and out when you push it. These plungers are used in electronics and plastic molds. They work gently with soft surfaces. There are different types of plungers. You can pick spring plungers, ball plungers, press fit ball plungers, or indexing plungers. Each type helps with different assembly problems.

Spring plungers have a spring that keeps the nose steady.

Ball plungers have a ball that goes back when pushed.

Press fit ball plungers fit tightly into plastic or wood.

Indexing plungers use a handle for fast removal.

You pick plungers based on what they are made of. Many plungers use Delrin or nylon. These materials are light and do not conduct electricity. They do not rust or make sparks. Some plungers are ESD-safe for electronics. ESD-safe plungers protect circuits from static.

Part | Material | Best Use Conditions |

|---|---|---|

Body | Delrin/Nylon | Light, non-conductive, no rust |

Tip | Nylon/Delrin | Soft metals, coatings, plastic or shiny parts |

You compare POM and PA to PEEK for tough jobs. POM and PA work for most tasks. PEEK is good for high heat and strong chemicals. You use PEEK plungers near hot runners or in harsh places. POM and PA plungers are best for everyday electronics and molds.

You want plungers that do not hurt soft plastics. Non-marring tips keep surfaces safe. ESD-safe plungers protect electronics from static. Spring ball plunger designs work quietly and smoothly. These plungers do not spark or scratch.

Miniature plungers fit in small spaces. Press fit ball plungers work well in plastic molds and electronics. You press these plungers in without threads. Small spring ball plungers help with tiny assemblies.

Plungers are used in many places. Electronics need spring ball plungers for circuit boards and connectors. Plastic molds use ball plungers to hold inserts or push out parts. You pick plungers for light weight, quiet use, and no rust.

Characteristic | Stainless Steel Ball Plungers | Delrin Ball Plungers |

|---|---|---|

Material Composition | Strong, does not rust | Slippery plastic, does not mark |

Applications | Planes, cars, boats | Electronics, medical, light jobs |

Performance Characteristics | Tough, lasts long, works in hard places | Smooth, good for soft materials |

Tip: Zhengchen Hardware has over 3,300 plungers. You can find the right spring ball plunger for your project, from tiny to heavy-duty styles.

A spring ball plunger holds parts gently. The spring pushes the ball tip out. When you press the ball, it goes back inside. This helps you slide or lock parts easily. The design makes movement smooth. It also helps parts last longer.

Feature | Ball Plunger | Spring Plunger |

|---|---|---|

Tip Design | Ball tip moves easily | Thin pin or nose |

Load Capacity | Usually lower | Handles heavier loads |

Construction | Uses lighter materials | Made with stronger materials |

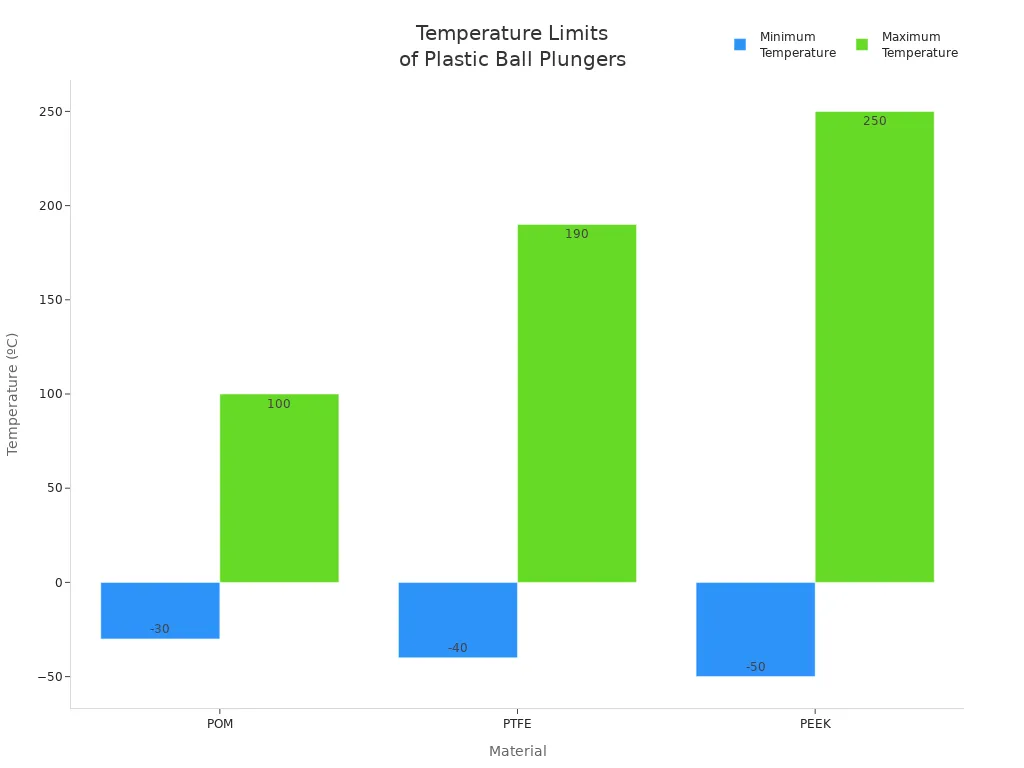

You need the right material for your plunger. POM works from very cold to warm. PTFE can handle higher heat. PEEK works best in very hot places. PEEK also stays strong with chemicals and heat.

Use PEEK plungers near hot runners. PEEK does not melt or get weak. POM and PA may get soft or wear out faster.

Delrin or nylon tips do not scratch soft plastics. These plungers last longer with polymer parts. You keep surfaces smooth and safe.

Some plungers have special coatings. Coatings help the ball move with less friction. This means less noise and longer use.

Ball plungers and spring plungers work differently. Ball plungers are good for accurate positioning. Spring plungers hold heavier things. Indexing plungers are fast for changes.

Feature | Ball Plungers | Spring Plungers |

|---|---|---|

Positioning Accuracy | Very accurate | A little less accurate |

Load Capacity | Holds lighter loads | Holds heavier loads |

Application Scenarios | Good for precise jobs | Used for many tasks |

Tip: Zhengchen Hardware has press fit ball plungers and small spring ball plungers for tight spaces. You can pick from over 3,300 plungers for your project.

Spring ball plungers work quietly and safely. They are light, so you can use them in electronics or plastic molds. These plungers do not make much noise when they move. They also do not make sparks, so your workspace stays safe. The tips do not scratch soft plastics or shiny parts. Old ball plungers can leave marks, but these do not.

Spring ball plungers use materials that do not rust. You can use them where there is water or chemicals. ESD-safe plungers stop static from hurting electronics. This keeps your circuits safe and working well.

You need to pick the right plunger for your job. Use the table below to help you choose:

Criteria | Description |

|---|---|

Physical Properties | Check if it is strong, tough, and lasts long. |

Injection Molding Capability | Think about how it melts and if it keeps its shape. |

Aesthetics and Dimensional Accuracy | Pick materials that look good and fit well in electronics. |

Chemical Exposure | Choose ones that can handle chemicals, like nylon or acetal. |

Weather Resistance | Use materials that last outside, even with sun or rain. |

Assembly Process | Think about how you will put the plunger in, like using glue. |

The material of your spring ball plunger helps it last longer. POM bodies and balls are strong and light. The plunger must be the right size for your machine or mold. Load ratings show how much force it can take. Spring ball plungers help you find, press, or push out parts in many ways.

POM bodies and balls are good for weight and wear.

You can use spring ball plungers to find, press, or push out parts.

Some jobs need special plungers. Zhengchen Hardware makes custom and small spring ball plungers. You can pick press fit ball plungers for tight spots or special shapes. The table below shows some choices:

Type of Micro Spring Plunger | Description | Customization Options |

|---|---|---|

Threaded Micro Spring Plungers | Easy to put in and adjust | Custom spring force, thread shapes |

Press-Fit or Smooth Body Micro Plungers | Good for small spaces, uses friction or glue | Special tip shapes, non-standard materials |

Ball-Type Micro Plungers | Low friction, works for moving parts | Custom shapes and materials |

Pin-Type Micro Plungers | Good for straight movement | Made for special needs |

Tip: You can use indexing plungers or spring plungers for quick changes or heavy loads. Zhengchen Hardware has many options for your project.

Spring ball plungers help electronics and plastic molds in many ways.

These plungers are lighter than metal ones. They do not rust easily. They cost less money.

You can pick plungers for small or tricky spaces.

Take care of your plunger by oiling it and checking it often. This keeps it working well.

Attribute | Description |

|---|---|

Durability | Spring ball plungers do not wear out fast. They can handle heat. |

Corrosion Resistance | Plungers work longer in wet places. |

Low Friction Properties | Spring ball plungers move easily. This saves energy. |

Precision Engineering | Ball plungers help you do careful and exact work. |

It is smart to buy spring ball plungers from trusted brands like Zhengchen Hardware. This tool helps you work safely, quietly, and with good results.

PEEK can handle more heat and strong chemicals. POM and PA are good for most regular jobs. Pick PEEK if you need to use it in hot or harsh places.

ESD-safe plungers stop static from hurting your circuits. They help keep your electronic parts safe when you put them together or use them.

Miniature plungers fit into very small spaces. Press-fit plungers are easy and fast to put in. These types are great for tiny or fragile parts.