+86-769-85303229 +86-13763283864 jennyguo@fazcwj.com

| Availability: | |

|---|---|

| Quantity: | |

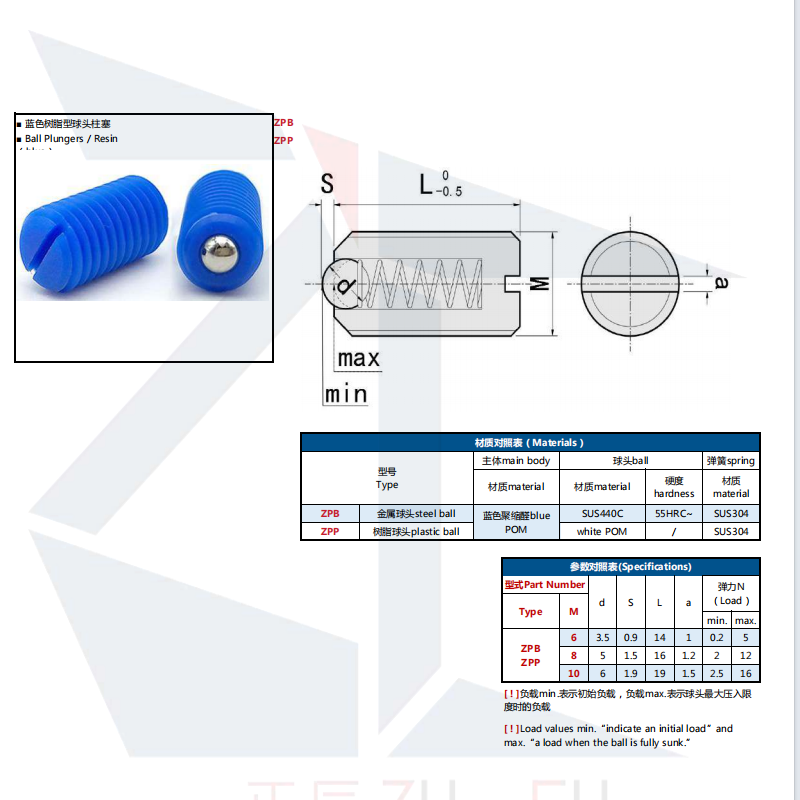

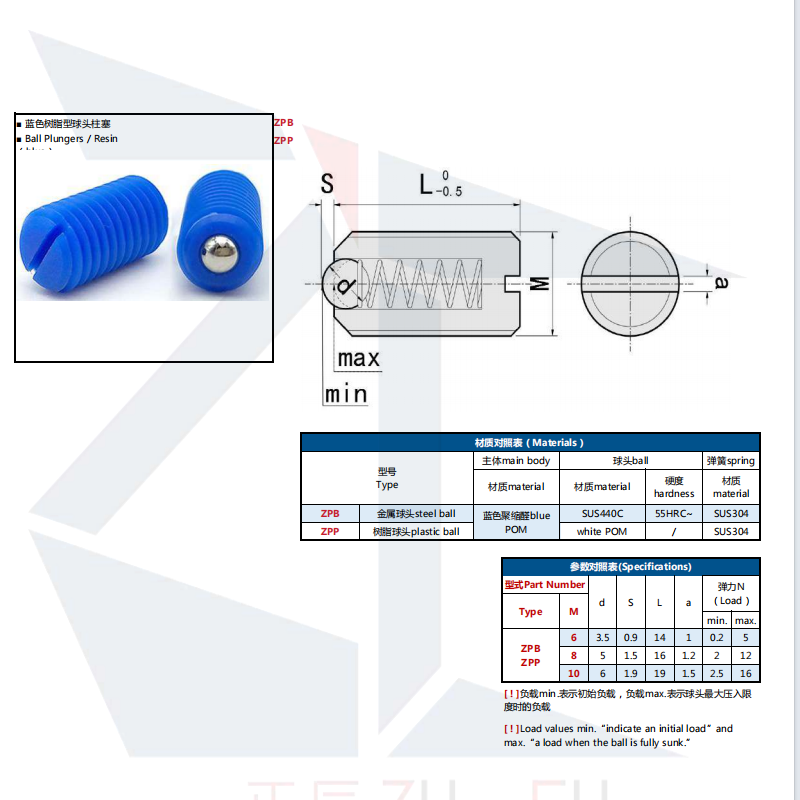

One of the key features of our Ball Plunger is its versatility. It can be used in a wide range of applications, from simple indexing and positioning tasks to more complex mechanical operations. The ball provides a point contact, which allows for precise movement and positioning. The spring-loaded design ensures that the ball remains in contact with the mating surface, even under varying loads and vibrations. Our ball plungers are available in a variety of sizes, shapes, and materials, allowing customers to choose the most suitable option for their specific needs. Some models also offer adjustable spring forces, providing further flexibility in different applications. Additionally, the threaded body makes it easy to install and remove the ball plunger, saving time and effort during assembly and maintenance.

The advantages of our Ball Plunger are numerous. Its versatility makes it a cost-effective solution for many industries, as it can be used in multiple applications without the need for different components. The precise movement and positioning capabilities ensure accurate operation, reducing errors and improving productivity. The spring-loaded design provides reliable performance, even in harsh environments, as it can withstand vibrations and shocks. The use of high-quality materials ensures a long service life, reducing the need for frequent replacements and minimizing downtime. The easy installation and removal process also contribute to the overall efficiency of the assembly and maintenance process. Moreover, our ball plungers are backed by a team of experienced engineers who can provide technical support and advice to ensure optimal performance.

Our Ball Plunger finds extensive applications in various industries. In the automotive industry, it is used for indexing and positioning components during assembly, ensuring precise fit and function. In the machinery manufacturing sector, it is employed for quick-release mechanisms, tool holders, and other applications where a reliable and easy-to-use locking solution is required. It is also commonly used in the electronics industry for holding and positioning circuit boards and components. Additionally, the ball plunger is suitable for applications in the aerospace, medical, and food processing industries, where precision and reliability are of utmost importance. In the furniture industry, it can be used for drawer stops and other types of positioning mechanisms.

Q: What is the maximum load capacity of the Ball Plunger?

A: The maximum load capacity of our Ball Plunger depends on the specific model and design. Generally, it can range from a few kilograms to several hundred kilograms. For detailed information on the load capacity of a particular model, please refer to the product specifications or contact our sales team.

Q: How do I install the Ball Plunger?

A: Installing the Ball Plunger is relatively simple. First, select the appropriate size and type of ball plunger for your application. Then, drill a hole with the correct diameter and depth in the mating surface. Thread the ball plunger into the hole using a suitable tool, such as a wrench or a screwdriver. Make sure to tighten the ball plunger firmly to ensure a secure fit. If you need to adjust the spring force, follow the instructions provided in the product manual.

Q: Can the Ball Plunger be customized?

A: Yes, we offer customization options for our Ball Plunger. We can customize the size, shape, material, spring force, and other features according to your specific requirements. Please contact our sales team to discuss your customization needs, and our engineers will work with you to develop a solution that meets your expectations.

One of the key features of our Ball Plunger is its versatility. It can be used in a wide range of applications, from simple indexing and positioning tasks to more complex mechanical operations. The ball provides a point contact, which allows for precise movement and positioning. The spring-loaded design ensures that the ball remains in contact with the mating surface, even under varying loads and vibrations. Our ball plungers are available in a variety of sizes, shapes, and materials, allowing customers to choose the most suitable option for their specific needs. Some models also offer adjustable spring forces, providing further flexibility in different applications. Additionally, the threaded body makes it easy to install and remove the ball plunger, saving time and effort during assembly and maintenance.

The advantages of our Ball Plunger are numerous. Its versatility makes it a cost-effective solution for many industries, as it can be used in multiple applications without the need for different components. The precise movement and positioning capabilities ensure accurate operation, reducing errors and improving productivity. The spring-loaded design provides reliable performance, even in harsh environments, as it can withstand vibrations and shocks. The use of high-quality materials ensures a long service life, reducing the need for frequent replacements and minimizing downtime. The easy installation and removal process also contribute to the overall efficiency of the assembly and maintenance process. Moreover, our ball plungers are backed by a team of experienced engineers who can provide technical support and advice to ensure optimal performance.

Our Ball Plunger finds extensive applications in various industries. In the automotive industry, it is used for indexing and positioning components during assembly, ensuring precise fit and function. In the machinery manufacturing sector, it is employed for quick-release mechanisms, tool holders, and other applications where a reliable and easy-to-use locking solution is required. It is also commonly used in the electronics industry for holding and positioning circuit boards and components. Additionally, the ball plunger is suitable for applications in the aerospace, medical, and food processing industries, where precision and reliability are of utmost importance. In the furniture industry, it can be used for drawer stops and other types of positioning mechanisms.

Q: What is the maximum load capacity of the Ball Plunger?

A: The maximum load capacity of our Ball Plunger depends on the specific model and design. Generally, it can range from a few kilograms to several hundred kilograms. For detailed information on the load capacity of a particular model, please refer to the product specifications or contact our sales team.

Q: How do I install the Ball Plunger?

A: Installing the Ball Plunger is relatively simple. First, select the appropriate size and type of ball plunger for your application. Then, drill a hole with the correct diameter and depth in the mating surface. Thread the ball plunger into the hole using a suitable tool, such as a wrench or a screwdriver. Make sure to tighten the ball plunger firmly to ensure a secure fit. If you need to adjust the spring force, follow the instructions provided in the product manual.

Q: Can the Ball Plunger be customized?

A: Yes, we offer customization options for our Ball Plunger. We can customize the size, shape, material, spring force, and other features according to your specific requirements. Please contact our sales team to discuss your customization needs, and our engineers will work with you to develop a solution that meets your expectations.

A standard indexing plunger is designed to re-engage automatically. That's great—until it isn't. In fast changeovers, rotating plates, or safety-critical adjustments, you may need the opposite behavior: the pin must stay retracted until the operator intentionally releases it.

When an indexing plunger "doesn't feel reliable," the issue is often not the plunger. It's the hole. Bore size, chamfer, and engagement depth decide whether the pin finds the target smoothly—or fights burrs, edge damage, and misalignment for the rest of its life.

Did you know that using the wrong set screw can cause permanent damage to delicate components? Whether you're working with polished aluminum, plastic housings, or precision assemblies, a traditional metal set screw might scratch, deform, or even crack your components.

What do medical devices, precision electronics, and high-end furniture have in common? They all require non-marring, precision fastening solutions—and nylon tip set screws are the go-to choice.Standard fasteners often cause more harm than good in delicate assemblies.

Did you know that a single fastener can determine whether your assembly lasts for years or fails within weeks? It's not always about the size or strength of the screw—it's about the application fit. In industries where surface integrity, vibration control, and precision are essential, the nylon tip set screw is often the unsung hero.

"One wrong screw can ruin your entire assembly." That's not an exaggeration—it's a reality many engineers and manufacturers face when choosing between different types of fasteners. Imagine tightening a set screw into a soft aluminum or plastic surface, only to find cracks, scratches, or permanent damage.

In many industries, fastening delicate components without causing surface damage is a constant challenge. That's where nylon tip set screws come in — a smart and reliable solution for non-marring, vibration-resistant fastening.

When you use a sliding door or open a drawer, you can feel the smooth stop and click. This comes from the ball head plunger and spring plunger inside. A high-quality ball head plunger uses strong materials like 304 stainless steel. This gives you better durability and protects against rust.

You use a plastic ball plunger to move parts gently. Material is important. POM and PA work for everyday jobs. PEEK is better for hot or tough places. Ball plungers keep electronics and molds safe. They protect soft surfaces.

Hygiene is very important in food processing. Every part, even a stainless steel ball plunger, must meet hygiene rules. Clean machines help keep food safe for people. Picking parts that resist germs and rust means you can trust your equipment for years.

You use spring ball plunger technology to get steady preload and close tolerances in your automation equipment. Spring-loaded plungers help you get exact positioning. This makes design and performance better.

Ever wondered what makes that satisfying "click" in knobs or fixtures? It’s often a spring plunger—a small part with a big job. From holding sliding doors in place to aligning machine components, spring plungers are everywhere. Choosing the wrong one can lead to loose fits or worn-out parts.

Ever wonder how machines get their parts to line up just right? That perfect fit often depends on small components like spring plungers. These parts help with positioning, clamping, and alignment in mechanical systems. But for even greater control, eccentric bushings come into play.

Ever wonder what gives that satisfying “click” in mechanical devices? It’s often thanks to a small part called a spring ball plunger. These tiny tools are powerful when used right—but easy to misuse.

Ever wondered how machines lock, click, or hold parts in place with precision? It’s often thanks to tiny tools called spring-loaded devices. Among them, spring plungers and ball plungers do the heavy lifting. But what exactly sets them apart—and why does it matter?

Ever wonder how machines lock parts perfectly into place? The secret is often a small but powerful tool called a spring plunger. These clever devices help position, lock, or release components with precision.

Zhengchen Hardware produces premium ball lock pins for industrial, automotive & machinery applications. Custom sizes & bulk pricing available. Request a quote today!Zhengchen Hardware – Your Trusted Ball Lock Pin ManufacturerWhen secure, quick-release fastening is critical, industries worldwide rely

Title: High-Quality Spring Plungers by Zhengchen Hardware – Precision & Durability for Industrial ApplicationsMeta Description: Zhengchen Hardware specializes in manufacturing premium spring plungers for machinery, automation, and OEM applications. Discover our reliable, customizable solutions today

Description: Zhengchen Hardware is a leading plunger manufacturer, offering durable, precision-engineered plungers at factory-direct prices. Custom solutions available. Request a quote now!Zhengchen Hardware – Your Trusted Plunger Manufacturer for Industrial ApplicationsWhen reliability and affordab

A spring loaded plunger is a small device with a spring inside. The spring pushes a pin or ball into place. It helps hold, lock, or position parts in equipment. People like it because it makes strong connections. It also lets you change things quickly.