+86-769-85303229 +86-13763283864 jennyguo@fazcwj.com

Spring Plungers with Flat Nose

• Shape: Push Up Type

• Wrench Hole Shape: Hex

• Body Material: 1045 Carbon Steel

• Main Body Surface Treatment: Black Oxide

• Nose Material: 1045 Carbon Steel

Dongguan Zhengchen Hardware Co., Ltd.

Main categories: Spring Plunger, Indexing Plunger, FA Automation Part

1.How long is your delivery time?

Generally our delivery time is 15 to 30 days . But different products and quantities have different procedures andtiming.we promise that we'll try our best to finish your orders within the shortest time.For more information, pleasecontact us.

2.ls the MOQ fixed?

For most orders,the MOQ can't be lowered according to the required quantities.For stock items,the quantities canbe negotiated.

3.What is the Surface Treatment?

Galvanized, Yellow zinc plated,H DG.

4.What is your material?

stainless steel and carbon steel .It also can according to your requirements.

5.Where is the port of shipment?

FOB:Shenzhen or HongKong.

6.What are your terms of payment?

PAYMENT BY T/T IN ADVANCE , West union,Paypal and etc.

7.Are customized products accepted?

You idea and imagine,we design and make.lt is fully self-customized.

8.Any discount possible if l place an order?

Yes,we have different price ranges (discounts)according to your quantities.You can consult us anytime.

9.Shipping

For samples or small order, can be delivered by express of DHL, UPS, FedEx,TNT, HKDC at the buyerconvenience, or by other express to save the buyer cost or shorten the transit time at the buyer request.& For mass order delivery, can be optional with terms of Ex-work, FOB by air or by sea based on the buyerforwarder or our recommended local forwarder at the buyer convenience.

To save the buyer shipping cost, we can also offer Chinese cheap cost from our local fonwarder for our buyer moreselections.

Spring Plungers with Flat Nose

• Shape: Push Up Type

• Wrench Hole Shape: Hex

• Body Material: 1045 Carbon Steel

• Main Body Surface Treatment: Black Oxide

• Nose Material: 1045 Carbon Steel

Dongguan Zhengchen Hardware Co., Ltd.

Main categories: Spring Plunger, Indexing Plunger, FA Automation Part

1.How long is your delivery time?

Generally our delivery time is 15 to 30 days . But different products and quantities have different procedures andtiming.we promise that we'll try our best to finish your orders within the shortest time.For more information, pleasecontact us.

2.ls the MOQ fixed?

For most orders,the MOQ can't be lowered according to the required quantities.For stock items,the quantities canbe negotiated.

3.What is the Surface Treatment?

Galvanized, Yellow zinc plated,H DG.

4.What is your material?

stainless steel and carbon steel .It also can according to your requirements.

5.Where is the port of shipment?

FOB:Shenzhen or HongKong.

6.What are your terms of payment?

PAYMENT BY T/T IN ADVANCE , West union,Paypal and etc.

7.Are customized products accepted?

You idea and imagine,we design and make.lt is fully self-customized.

8.Any discount possible if l place an order?

Yes,we have different price ranges (discounts)according to your quantities.You can consult us anytime.

9.Shipping

For samples or small order, can be delivered by express of DHL, UPS, FedEx,TNT, HKDC at the buyerconvenience, or by other express to save the buyer cost or shorten the transit time at the buyer request.& For mass order delivery, can be optional with terms of Ex-work, FOB by air or by sea based on the buyerforwarder or our recommended local forwarder at the buyer convenience.

To save the buyer shipping cost, we can also offer Chinese cheap cost from our local fonwarder for our buyer moreselections.

Spring plunger, also known as positioning column, wave screw, spring screw, etc., presses the front end pin until it sinks into the body, and relies on the built-in spring to push the front end pin out. It belongs to the product of up and down travel and can be used for mold demolding and workpiece lifting,

Positioning and other applications can be widely used in low to medium precision mechanical devices, fixtures, molds, automation machinery, etc. "

Product Features

The material of each pin on the main body is steel.

For products with the same thread size, there are two specifications available for pin travel.

♢ Spring plunger is a product with up and down strokes, which can be used for mold demolding, workpiece lifting, positioning, etc. It can be widely used in medium and low precision mechanical devices, fixtures, molds, automation machinery, etc.

Spring plunger, also known as positioning column, wave screw, spring screw, etc., presses the front end pin until it sinks into the body, and relies on the built-in spring to push the front end pin out. It belongs to the product of up and down travel and can be used for mold demolding and workpiece lifting,

Positioning and other applications can be widely used in low to medium precision mechanical devices, fixtures, molds, automation machinery, etc. "

Product Features

The material of each pin on the main body is steel.

For products with the same thread size, there are two specifications available for pin travel.

♢ Spring plunger is a product with up and down strokes, which can be used for mold demolding, workpiece lifting, positioning, etc. It can be widely used in medium and low precision mechanical devices, fixtures, molds, automation machinery, etc.

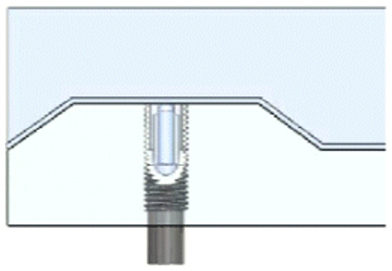

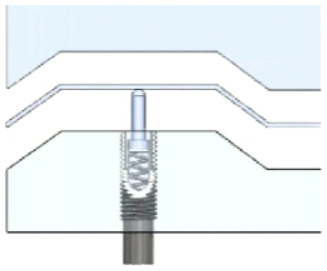

Use Cases

When pressing down

When releasing

usage method

Plunger block and plunger are integrated products. The supporting adjustment screws can be used to adjust the position of the workpiece.

usage method

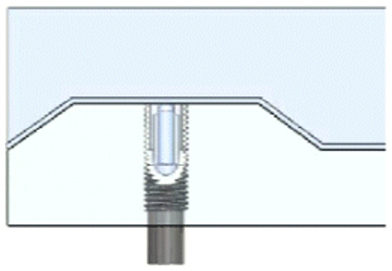

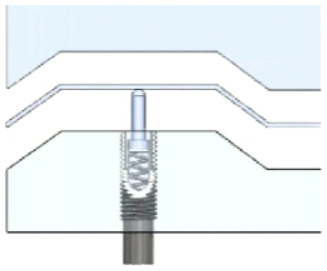

Use Cases

When pressing down

When releasing

usage method

Plunger block and plunger are integrated products. The supporting adjustment screws can be used to adjust the position of the workpiece.

usage method

Did you know that using the wrong set screw can cause permanent damage to delicate components? Whether you're working with polished aluminum, plastic housings, or precision assemblies, a traditional metal set screw might scratch, deform, or even crack your components.

What do medical devices, precision electronics, and high-end furniture have in common? They all require non-marring, precision fastening solutions—and nylon tip set screws are the go-to choice.Standard fasteners often cause more harm than good in delicate assemblies.

Did you know that a single fastener can determine whether your assembly lasts for years or fails within weeks? It's not always about the size or strength of the screw—it's about the application fit. In industries where surface integrity, vibration control, and precision are essential, the nylon tip set screw is often the unsung hero.

"One wrong screw can ruin your entire assembly." That's not an exaggeration—it's a reality many engineers and manufacturers face when choosing between different types of fasteners. Imagine tightening a set screw into a soft aluminum or plastic surface, only to find cracks, scratches, or permanent damage.

In many industries, fastening delicate components without causing surface damage is a constant challenge. That's where nylon tip set screws come in — a smart and reliable solution for non-marring, vibration-resistant fastening.

When you use a sliding door or open a drawer, you can feel the smooth stop and click. This comes from the ball head plunger and spring plunger inside. A high-quality ball head plunger uses strong materials like 304 stainless steel. This gives you better durability and protects against rust.

You use a plastic ball plunger to move parts gently. Material is important. POM and PA work for everyday jobs. PEEK is better for hot or tough places. Ball plungers keep electronics and molds safe. They protect soft surfaces.

Hygiene is very important in food processing. Every part, even a stainless steel ball plunger, must meet hygiene rules. Clean machines help keep food safe for people. Picking parts that resist germs and rust means you can trust your equipment for years.

You use spring ball plunger technology to get steady preload and close tolerances in your automation equipment. Spring-loaded plungers help you get exact positioning. This makes design and performance better.

Ever wondered what makes that satisfying "click" in knobs or fixtures? It’s often a spring plunger—a small part with a big job. From holding sliding doors in place to aligning machine components, spring plungers are everywhere. Choosing the wrong one can lead to loose fits or worn-out parts.

Ever wonder how machines get their parts to line up just right? That perfect fit often depends on small components like spring plungers. These parts help with positioning, clamping, and alignment in mechanical systems. But for even greater control, eccentric bushings come into play.

Ever wonder what gives that satisfying “click” in mechanical devices? It’s often thanks to a small part called a spring ball plunger. These tiny tools are powerful when used right—but easy to misuse.

Ever wondered how machines lock, click, or hold parts in place with precision? It’s often thanks to tiny tools called spring-loaded devices. Among them, spring plungers and ball plungers do the heavy lifting. But what exactly sets them apart—and why does it matter?

Ever wonder how machines lock parts perfectly into place? The secret is often a small but powerful tool called a spring plunger. These clever devices help position, lock, or release components with precision.

Zhengchen Hardware produces premium ball lock pins for industrial, automotive & machinery applications. Custom sizes & bulk pricing available. Request a quote today!Zhengchen Hardware – Your Trusted Ball Lock Pin ManufacturerWhen secure, quick-release fastening is critical, industries worldwide rely

Title: High-Quality Spring Plungers by Zhengchen Hardware – Precision & Durability for Industrial ApplicationsMeta Description: Zhengchen Hardware specializes in manufacturing premium spring plungers for machinery, automation, and OEM applications. Discover our reliable, customizable solutions today

Description: Zhengchen Hardware is a leading plunger manufacturer, offering durable, precision-engineered plungers at factory-direct prices. Custom solutions available. Request a quote now!Zhengchen Hardware – Your Trusted Plunger Manufacturer for Industrial ApplicationsWhen reliability and affordab

A spring loaded plunger is a small device with a spring inside. The spring pushes a pin or ball into place. It helps hold, lock, or position parts in equipment. People like it because it makes strong connections. It also lets you change things quickly.

The cam action indexing plunger market is getting bigger. This is because more cars, planes, and medical devices are being made. The market was worth $2.1 billion in 2023. Experts think it will grow to $3.8 billion by 2032.

You often see T-handle, L-handle, and cam lever designs when selecting an indexing plunger with handle. Each style offers a unique way to move, adjust, and lock parts securely in place. T-handle plungers are ideal for machining, positioning, and aligning components.